The invention, known as a liquid-liquid encapsulation system, generates a drop of liquid ingredient through a nozzle, which gravitationally drops into a bath of liquid material that provides a liquid shell coating around the droplet. Through careful configuration of the system, a core-shell stable encapsulation is formed that protects the core material and safeguards it from an aggressive environment enabling unique formulations that can be designed to time release the cargo depending on the needs of the application.

“The key to this technology is that everything is in liquid state – the core, the shell, and finally submerged inside a liquid bath. This provides extraordinary flexibility in terms of core shell combinations. At least 15 of these types of combinations have already been demonstrated” said Sushanta Mitra, executive director, Waterloo Institute for Nanotechnology and professor of Mechanical & Mechatronics Engineering. "It is ultrafast with each encapsulation taking only 50 milliseconds. This technology is at least 5000 times less energy intensive and it avoids the introduction of any microplastics in the encapsulation process.”

This technology could be useful in the nutraceutical, pharmaceutical, food and beverage, cosmetic and personal care industries. For example, the use of soft gel filling encapsulation machines in the nutraceutical industry could reduce operating costs and expand development and production of new products as multiple core materials can be encapsulated and delivered in the same parcel.

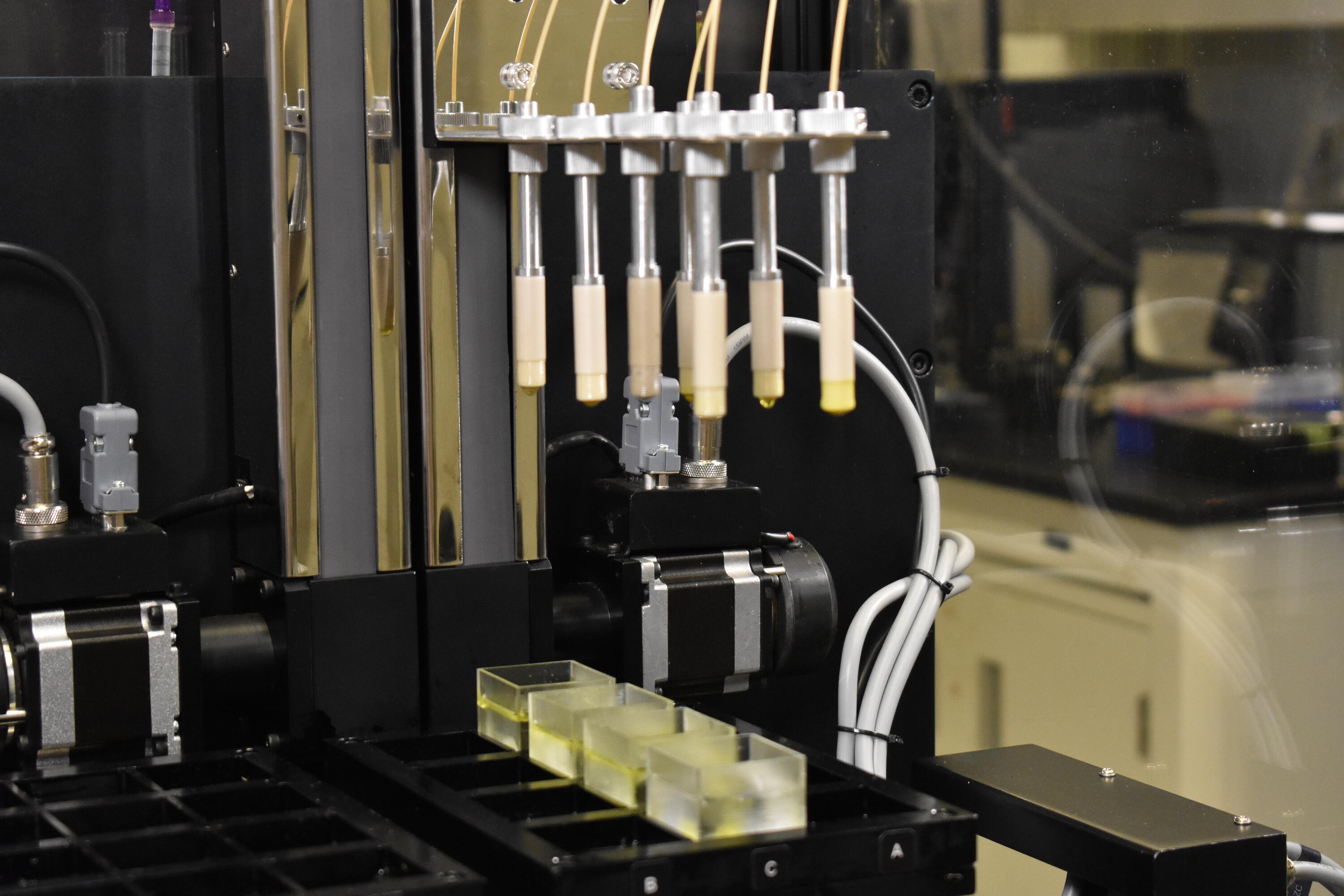

Dr. Mitra and his team have developed a robust prototype with four injection nozzles that can deliver up to 200,000 encapsulated cargo in an hour. The Waterloo Commercialization Office (WatCo) has supported this project by filing formal patent applications and facilitating commercial agreements with partners in the Netherlands to assist with engineering scale-up and process optimization activities.

“In the end we strive toward being a sustainable and innovative encapsulation entity that meets the UN sustainable development goals” said Dr. Mitra.