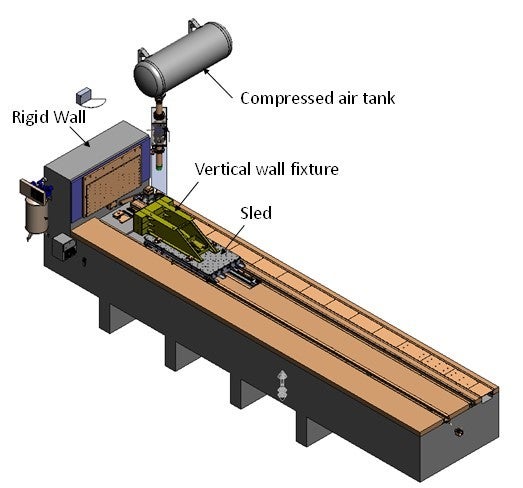

The UWaterloo Structural Crashworthiness Crash Sled Facility consist of a Seattle Safety impact sled, with a maximum available impact energy of 169,500 J. Maximum allowable payload is 1,400 kg. The sled size is 2,500 mm x 1,200 mm and can accommodate a payload of up to 1,400 kg.

Data Acquisition

- The sled data acquisition system is capable of recording loads, accelerations, high speed video and high speed infra-red video.

-

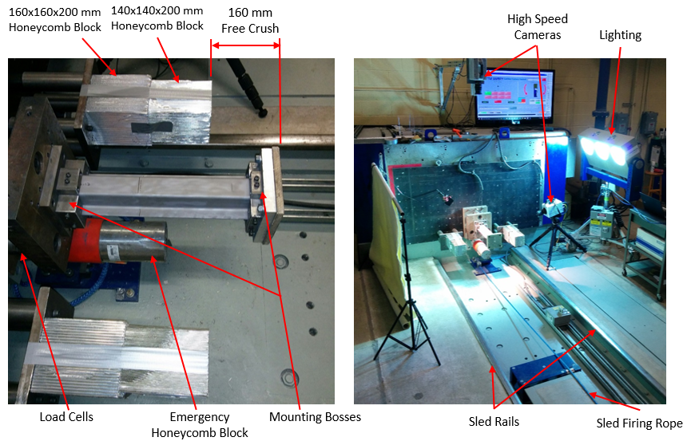

Six Kistler Quartz Force Link (model #9371B) load cells rated for ± 120 kN are available for force measurements. They load cells can be mounted on the wall or on the sled.

-

Sled acceleration is measured using two MSI accelerometers (model # 64B-0100-004) mounted on the front of the sled. The load cell and accelerometer data are recorded using on board and wall mounted DTS Slice data acquisition systems.

-

High speed video of the tests can be recorded using up to three Photron high speed cameras (one SA-4 and two SA-5s), which are capable at recording at frame rates in excess of 100,000 frames per second (fps). Typically, tests are recorded at 5,000 fps which provides high definition quality video of the tests.

-

A Telops FAST-IR 2K thermal camera is available for high speed infra-red video.

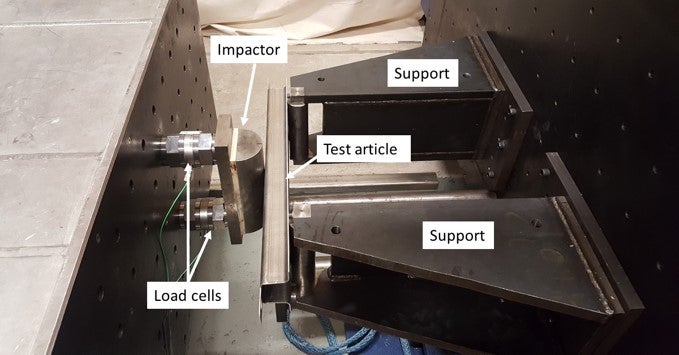

Experimental Setup

Dynamic crash setup for axial crush

Dynamic crash setup for three-point bends

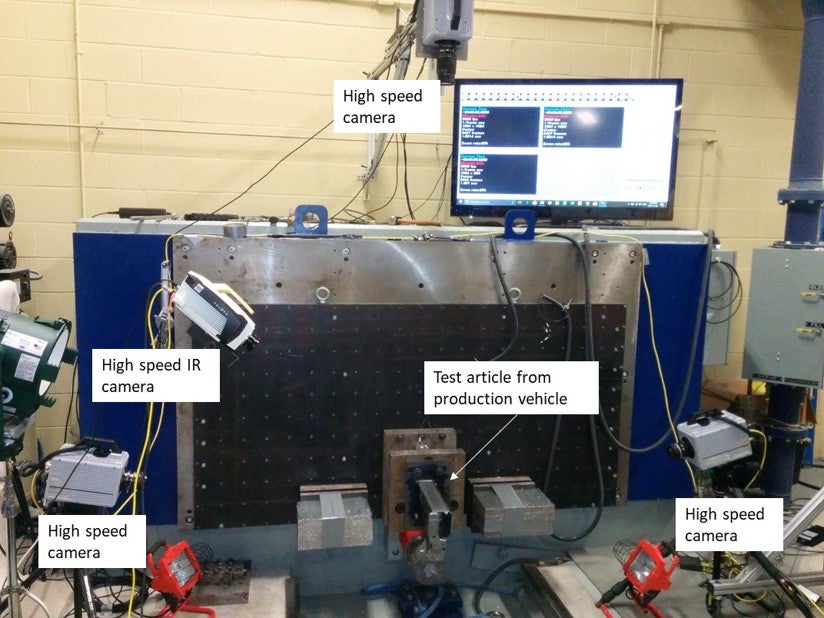

Testing of production components

The impact can be used to test experimental samples as well as production components. The image below shows an experimental set up for a production front rail section. Three Photron high speed cameras were used to record the deformation, together with a Telops high speed IR camera.

For more on sample testing, see our page on Crash Testing and Modelling of Structural Components.